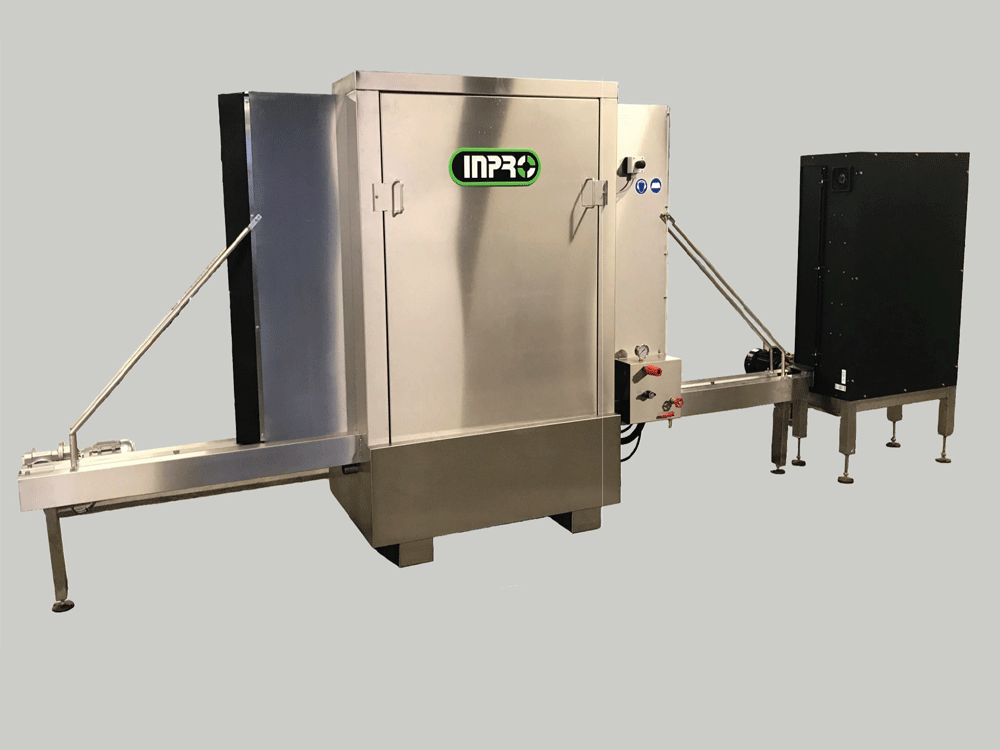

Simplicity in performance

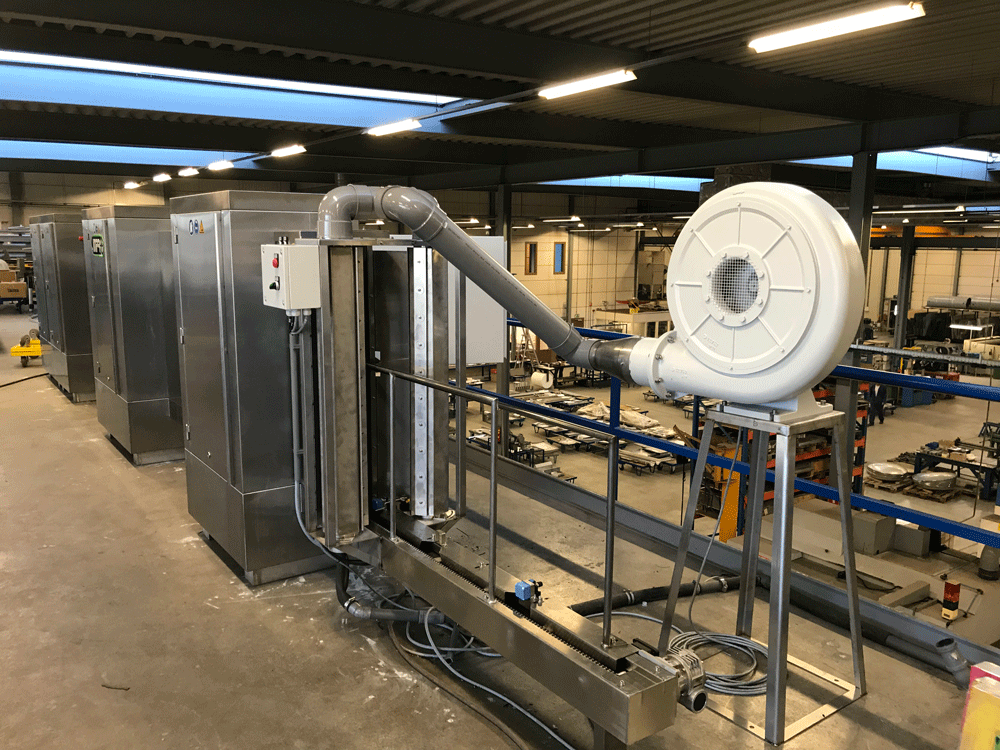

We stand for ‘Simplicity in performance’, which means we deliver machines that give an excellent performance and are simple in use. Our Tigerclean series realize this through fully automatic machines without difficult computer programs to operate the machines. Our Tigerclean series are modulair designed, and we can offer customized screen cleaning/reclaiming/developing machines and special chemicals. Together with the Inpro technology it will give the screen printer the desired results.

WHO WE ARE

Inpro has been the reliable business partner for more than 25 years in process improvements for the screen- and large format digital printing companies. Inpro strives for taking process bottlenecks away, and develops more (cost) efficient, safer, greener, high quality machines as well as chemicals, which must be simple in use and will lower your overall costs.

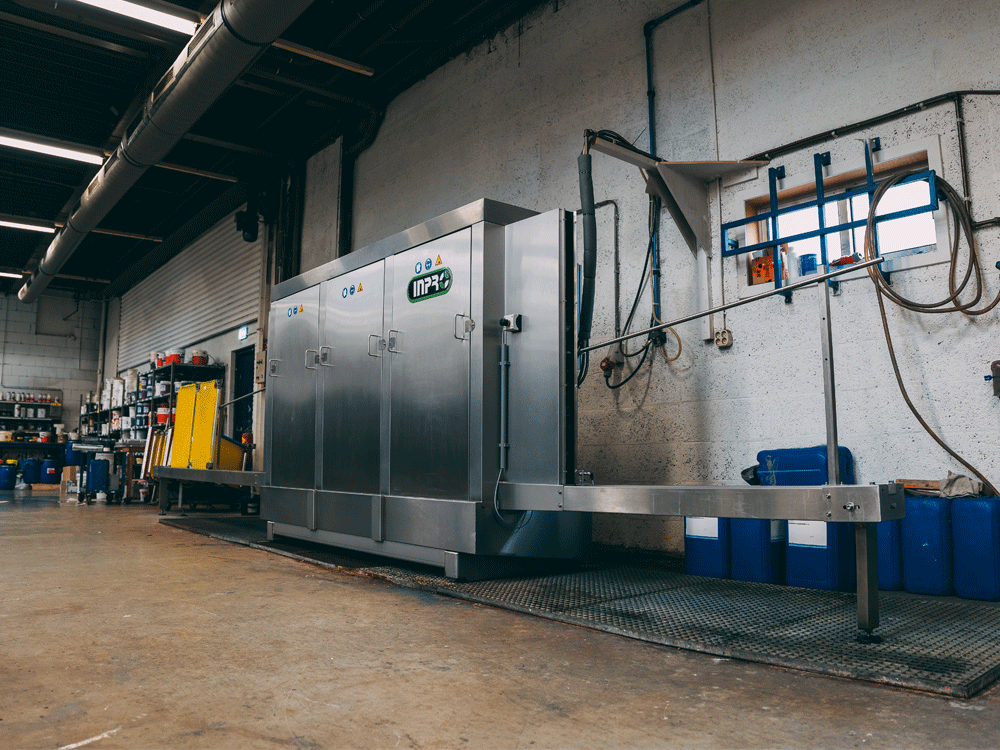

Maintenance

Our machines are especially developed as easy to maintain machines. During the installation we, or our resellers intensively train your operators and technician for the operation as well as for the maintenance. We offer specific extensive manuals and instruction movies to facilitate in the operations and maintenance of the machines. Our engineers are available for all the customers that encounter technical difficulties or where any help is needed. In order to improve the life span of our machines we deliver the best parts, and our technicians make preventive maintenance visits.

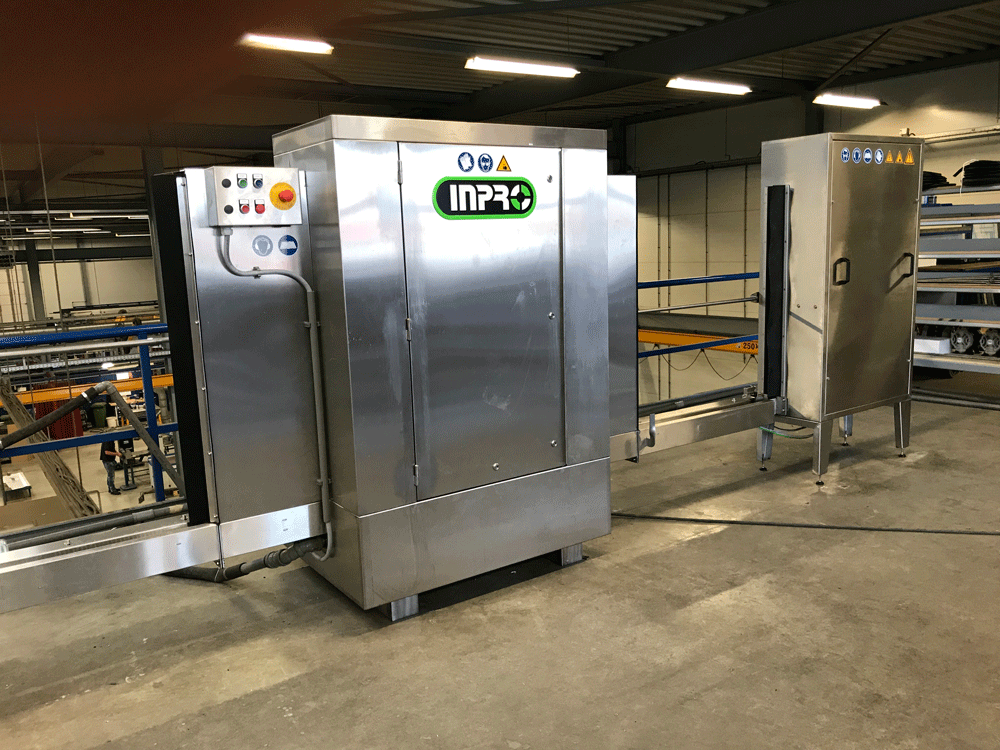

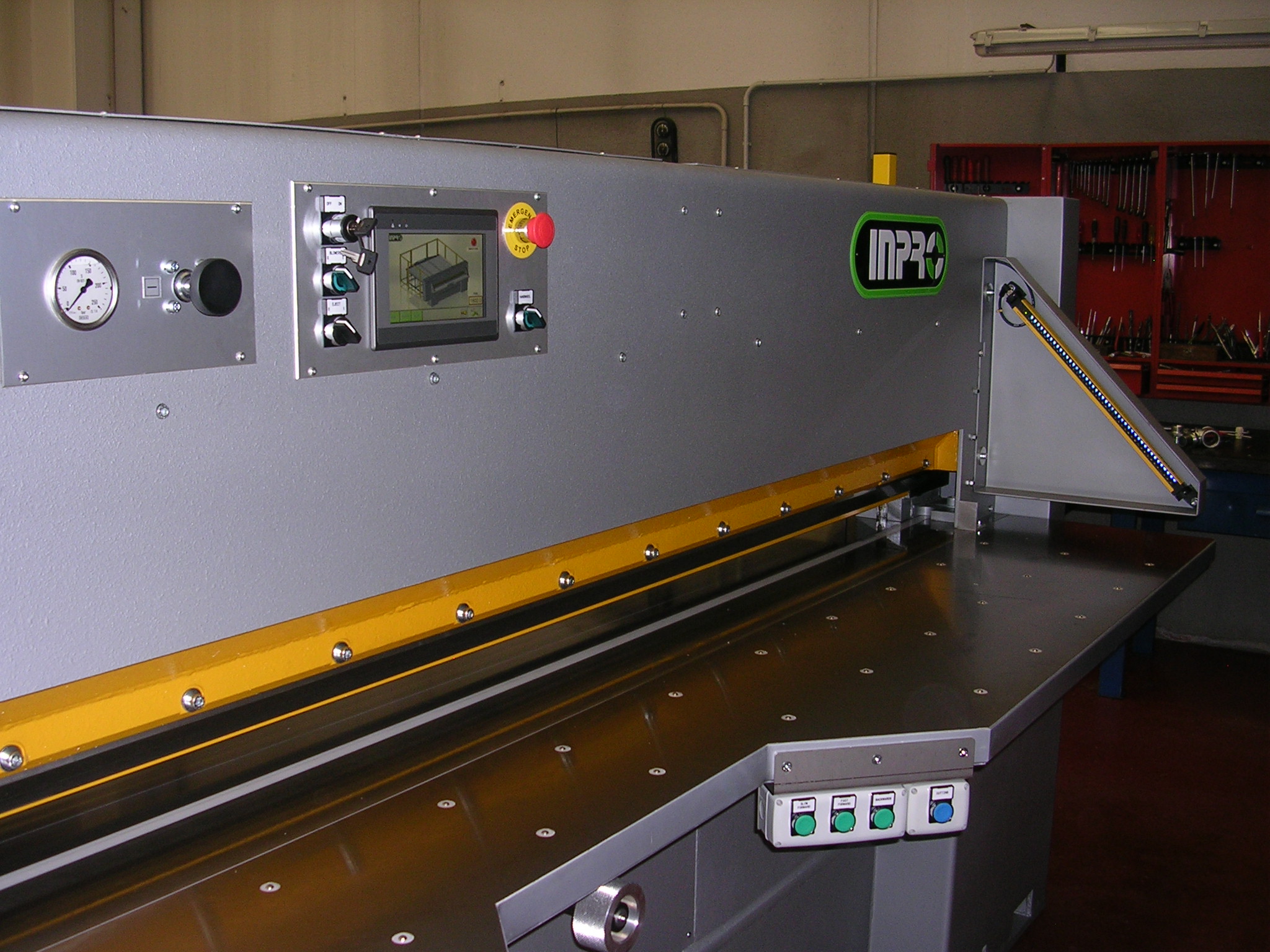

Safety

We believe that the finishing process needs to be the safe for the people who are active in the finishing process, and the environment. Therefore we deliver the Inpro special cutters with the highest safety level CE and EN1010. For our Tigerclean series we develop continuously new environment friendlier chemicals for the highest safety and the machines are completely CE-safe